Revolutionizing Industrial Monitoring

Unified Wireless Vibration Software Systems

Wireless vibration sensors are increasingly critical for machinery maintenance and monitoring in the rapidly evolving industrial sector. These sensors provide real-time data essential for predictive maintenance, helping to prevent costly downtimes and enhance operational efficiency. Despite their benefits, sensors’ diversity and software systems present significant challenges and opportunities.

Today’s Fragmented Ecosystem: Challenges and Opportunities

Advantages of Diversity

The current landscape of wireless vibration sensor systems features diverse software solutions, each designed to meet specific customer requirements while helping to optimize operational requirements.

Utilizing multiple systems can enhance operational resilience while being able to cater to different processes and machinery. This setup also avoids vendor lock-in, mitigating risks associated with dependency on a single provider. This fragmentation also allows for cost-effective scaling across a diversity of processes and equipment.

Disadvantages of System Diversity

However, managing a fragmented array of systems increases operational complexity and the likelihood of integration issues, complicating data aggregation and analysis. This can lead to higher long-term costs, as maintaining several software systems is complicated and distracts from core business functions, potentially impacting productivity.

Separate systems also create data silos, obstructing a unified operational view and slowing down decision-making processes. Moreover, diverse systems increase the risk of data breaches.

Our Future-Ready Solution: A Unified Monitoring Platform

To address these challenges, we have developed an innovative, comprehensive, and sensor-agnostic platform specifically designed for wireless vibration sensors in industrial settings. This solution is crafted to streamline the monitoring process at every layer, ensuring that businesses can fully leverage the potential of IoT and predictive maintenance.

Key Features of Viking Analytics MultiWiz platform:

- Advanced Analytics and Threshold-Free Smart Alarms: Powered by AI, our platform predicts potential failures and triggers health-related warnings automatically, irrespective of the machine type or sensor brand. No manual setting of thresholds is needed.

- Seamless Sensor Integration: Our platform supports various sensors regardless of their manufacturer, facilitating easy integration of legacy systems while standardizing new deployments.

- Minimal Dependency on Machine Meta Information: Our models primarily rely on raw vibration data, not on the meta information of the machines.

- Centralized Data and Model Management: Our solution enables customers to centralize data management using standard solutions available in the market while allowing the development of predictive models based on collected data and utilizing third-party models from OEMs or other vendors.

- Scalability and Customization: The platform easily scales to accommodate growing data volumes and diverse operational needs, ensuring specific monitoring requirements are met.

Impact and Benefits

- Reduced Complexity: Our platform simplifies monitoring by eliminating the need to manage multiple software systems and data silos.

- Faster Response Times: Integrated data analytics enhance decision-making capabilities, reducing downtime and extending machinery lifespan.

- Cost Efficiency: The system improves maintenance schedules and reduces unnecessary repairs, thereby cutting down operational costs.

Conclusion

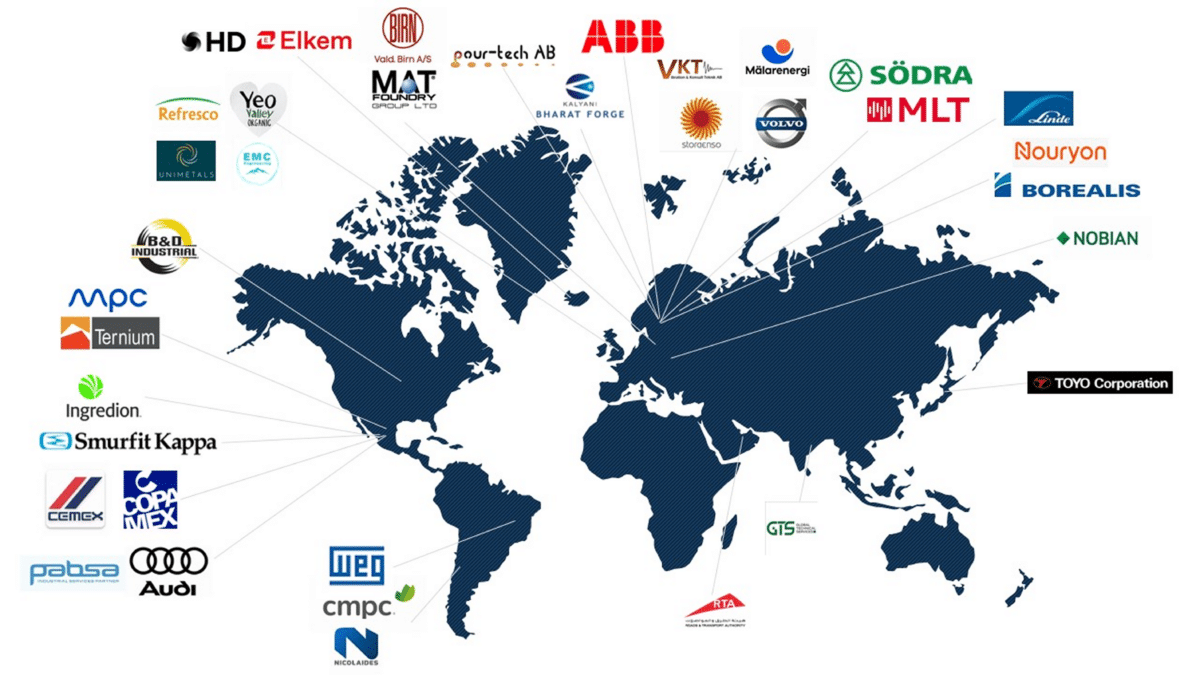

For industrial companies aiming to fully leverage IoT and predictive maintenance, our unified platform for wireless vibration sensors is not just a technological upgrade—it’s a strategic overhaul. By consolidating sensor integration and data analysis with minimal dependency on machine metadata and threshold settings, our solution empowers businesses to proactively manage their machinery, ensuring operational continuity and driving significant improvements in efficiency and productivity. This comprehensive approach not only streamlines operations but also sets a new standard for industrial monitoring systems.